■起动前准备 Ready before starting

·用手拨动电机风叶,叶轮应无卡磨现象,转动灵活

Moving the motor vane by hand. the impeller shouldnt rub, the rotation is nimble.

·打开进口阀门、打开排气阀使液体充满整个泵腔,然后关闭排气阀。

Open inlet valve and discharge valve to fill whole pump with liquid, then close discharge valve after it is full

·用手盘动泵以使润滑液进入机械密封端面

Start pump by hand, to make lubrication enter into mechanical seal surface.

·点动电机,确定转向是否正确。

Start motor, check revolving direction is right or not

起动与运行 Start and running

·全开进口阀门,关闭吐出管路阀门

Full-open inlet valve, close the valve of discharge pipeline

接通电源、当泵达到正常转速后,再逐渐打开吐出管道路上的阀门,并调节到所需工况。

Turn on power source, open the valve on discharge pipeline to regulate work condition after revolving speed of pump

keep normal.

·注意观察仪表读数,检查轴封泄漏情况,正常时机械密封泄漏量(3滴/分,填料泄漏量(10mh

Observing gauge data carefully, checking the leakage condition of shafts seal. when it is normal, the leakage quantity

of mechanical seal is<3 drop/minute, the leakage quantity of stuffing is <10 ml/h.

·检查电机、轴承处温升≤70℃,如果发现异常情况,应及时处理

Check the motor and bearing, its temperature should be <70C, if they aren't normal, it should treat in time.

停车Stop

·逐渐关闭吐出管路阀门,切断电源。

Close the valve of discharge pipeline, tum off power source

关闭进口阀门

Close the valve of inlet

如环境温度低于0℃,应将泵内液体放尽,以免冻裂。

If ambient temperature is lower than oC, all the liquid in pump should discharge to avoid freezing and cracking

如长期停用,应将泵拆卸清洗,加防锈油,包装保管。

If unit keeps stop condition for long time, we should disassemble pump and coat rust-proof grease on it

运行中的维护 Maintenance during operation

·进口管道必须充满液体、禁止泵在汽蚀状态下长期运行

Inlet pipeline should full with liquid, prohibit pump to operate in cavitate condition;

定时检查电机电流值,不用超过电机额定电流。

Check the current value of motor periodically, it shouldnt higher than rated current of motor:

·泵进行长期运行后,由于机楲磨损,使机组噪音及振动增大时,应停车检查,必要时可更换易损件,机组大修期一般为一年。

If pump operates for long time, you should replace damageable parts and check unit periodically the check time is one

year in a general way.

机构密封维护 Maintenance for mechanism seal

机构密封润滑应清洁无固体颗粒

The lubrication of mechanism seal should clean without solid particle.

·严禁机构密封在干磨情况下工作

hibiting mechanism seal working in the dry grinding condition.

起动前应先盘动泵(电机)几圈,以免突然起动造成石墨环断裂损坏。

Start pump (motor)for several circle before starting, to avoid graphite ring to be damaged.

密封泄漏允差3滴/分,否则应检修。

The leakage tolerance of mechanical seal is about 3 drop/ minute, or else if should be checked.

装配与拆卸 Assemble and disassemble

装配转子部件:依次将叶轮、叶轮螺母、轴套、填料套、填料环、填料压盖、挡水圈、轴承部件装在泵轴上,并套上双吸密封

环,然后装上联轴器

Assemble the rotors parts: Mounting the impeller, impeller nut, shaft sleeve, stuffing sleeve, stuffing ring, stuffing gland.

water retaining ring, bearing on the pump shaft in turn, and putting on duak-suction seal ring, then installing the coupling

将转子部件装在泵体上,调整叶轮的轴向位置到双吸密封环的中间加以固定,将轴承体压盖同固定螺钉坚固

Mount the rotor on the pump casing adjusting the impeller to have its axial position in the middle of the dual-suction se

ning and then fixed, then fixing the gland of bearng s body with the terminal screw.

·装上填料,放好中开面纸垫,盖上泵盖打紧螺尾柱销后,拧紧泵盖螺母,最后装上填料压盖。但不要将填料压得太紧

紧会使轴套发热,耗费功率较大,也不要压得太松,过松会使液体渗漏大,水泵效率降低。装配完成后,用手转动泵轴

擦碰现象,转动比较轻滑均匀即可,拆卸可按上述装配顺序相反进行。

Put on the stuffing the paper pad on the middle opened surface and the pump cover and tighten the threaded-tail c-

onical pin first and the pump's cover nut, then mounting the stuffing gland. But do not press the stuffing too tightly, othe-

rwise the shaft sleeve may get heated to leave a bigger power consumption; while not too loose, or else may result in a

big leakage of liquid and reduced pump efficiency. After assembly, move the pump shaft by hand. it should be smooth

d unifom without rubbing, disassembly can be made with the above steps contrary.

安装说明 The instruction of installation

检查水泵和电动机应无损坏

and motor to see if there are any damages with them

水泵的安装高度,加上吸入管路的水力损失,及其速度能,不得大于样本规定的允许吸上真空高度值。基础尺寸应符合泵机组

e installation height of the pump plus the hydraulic loss of the suction pipeline and its speed energy is just the NPSHa of

the unit, which should be higher than NPSH the dimension of the basis should be in line with those of installation of the

安装顺序 nstallation sequ

1.将水泵放在埋有地脚螺栓的混凝土基础上,有调整其间的楔型垫块的方法校正水平,并适当拧紧地脚螺栓,以防走动

Place the pump on the concrete basis with built-in foot bolts, correct the levelness with the method adjusting the wedge

ushion block and property tighten the bolts to prevent them from displacem

2在基础与泵地脚之间灌注混凝土;

Grout concrete between the basis and the pump foot:

3待混凝土干固后,拧紧地脚螺栓,并重新检查水泵的水平度;

After the concrete gets solidified, tighten the foot bolts and check the pump,s levelness again

4校正电动机轴与泵轴的同心度。使两轴成一直线,在两轴外圆上的同轴度允差为0mm,端面间隙沿圆周的不均匀度允差

0.3mm(在联接进出水管路及试运行后再分别校正一遍,仍应符合上述要求

Correct the concentricity between the axles of pump and motor to have them in a straight line. The allowed tolerance of

he non-concentricity of the outer circles of two couplings is o I mm and the one of the non-uniform end-surface intervals

along with the circumference is 0. 3mm(another correction after connecting inlet and outlet pipelines and trial movement,

the above requirement should also be met with

5在检查电动机转向与水泵转向一致后,装上联轴器及联接柱销。

After finding out the rotating direction of the motor is identical to that of the pump, mounting the link pin of the coupling

Both inlet and outlet pipelines should be supported by a separate stand and not by the pump body:

水泵与管路之间的结合面,应保证良好的气密性,尤其是进水管路,应严格保证不漏气,并且在装置上应无窝存空气的可能

a good air tightness of the combined surface between pump and pipe line should be kept, especially the inlet pipeline, it

must be guaranteed without air leak and without the possibility for air to be nested on the unit

如水泵安装在进水水位上时,为了灌泵起动,一般可装底阀。也可采用真空引水的方法;

In general, a foot valve can be mounted if the pump is mounted above the water level of the inlet so as to start the pump

with priming, it can also use the way of

m pump water leading:

水泵与出水管路之间一般需装闸阀和止回阀(扬程小于20mm的可不用),止回阀装在闸阀后面。

In general, gate valve and check valve are required to be mounted in the outlet pipeline of the pump(unnecessary for

those of a head less than 20m), with the check valve mounted after the gate valve

以上所述的安装方法是指不配带公共底座的水泵机组;

The above mentioned methods of installation mean the pump without a common foundation:

安装配带公共底座的泵,用调整底座与混凝土基础之间的模形垫铁来校正机组的水平。然后在其间灌注混凝土,其安装原则与

要求,和不配带公共底座的机能相同

For the pump with a common foundation, use the wedge iron-pad between foundation and concrete to corect the le-

elness of the unit, then grout concrete between them. The installation principle and requirement are the same as those

for the pump without a common foundation.

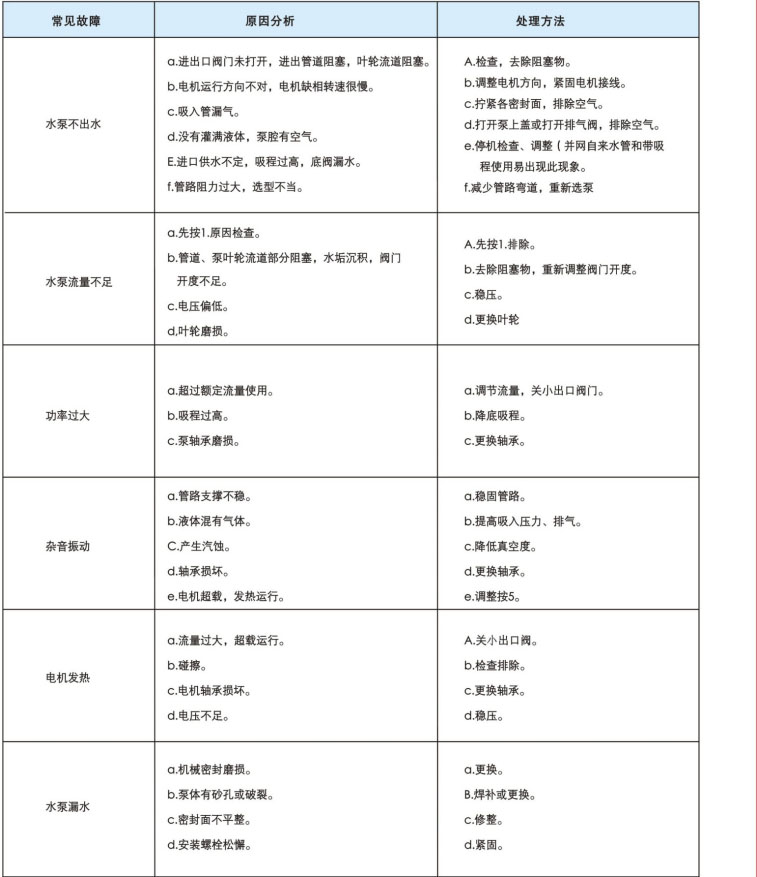

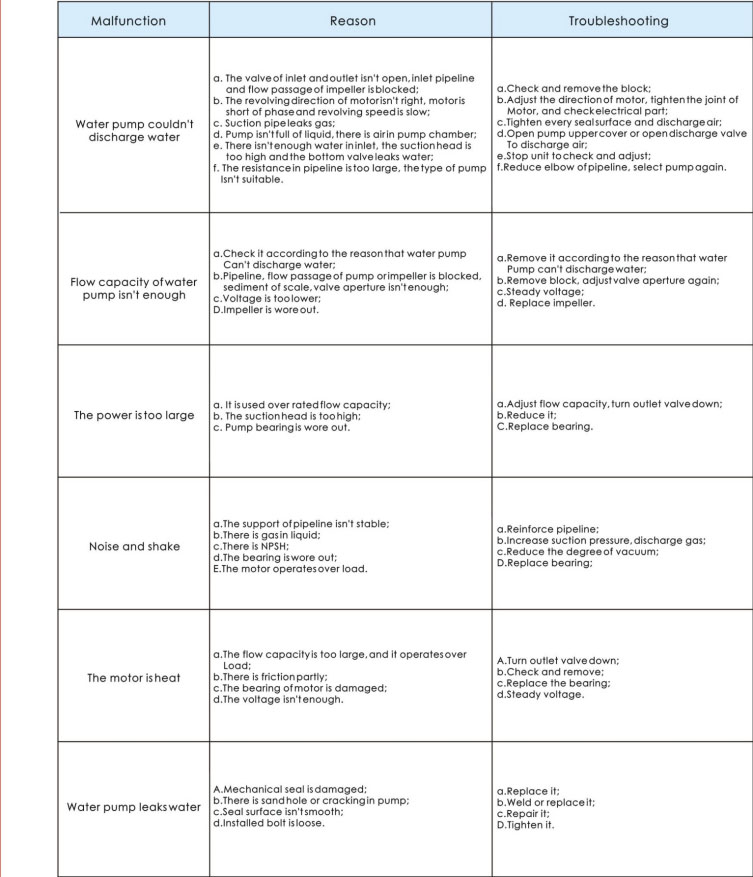

故障原因及排除方法:

© 2023 上海浙瓯泵阀制造有限公司 版权所有

© 2023 上海浙瓯泵阀制造有限公司 版权所有