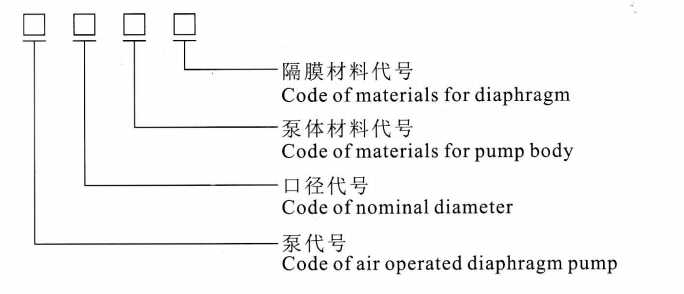

隔膜泵型号编制方法 Establishment method of pump model

泵型号由四个单元组成按下列顺序编制

The pump model is composed of four units and is established according to the following sequence

口径代号 Code of nominal diameter:8(5/16),10(3/8),15(1/2),25(1),40(11/2),50(2),80(3)

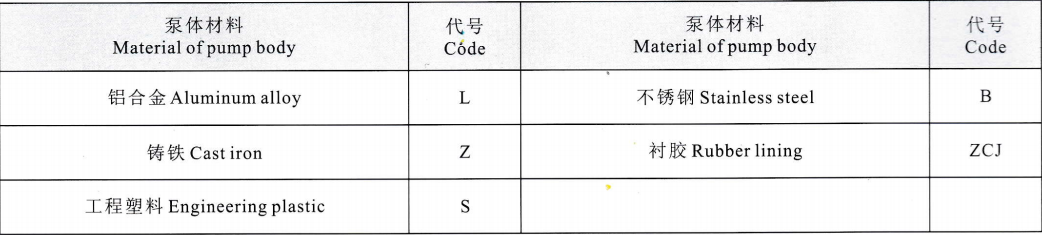

泵体材料代号 Code of materials for pump body

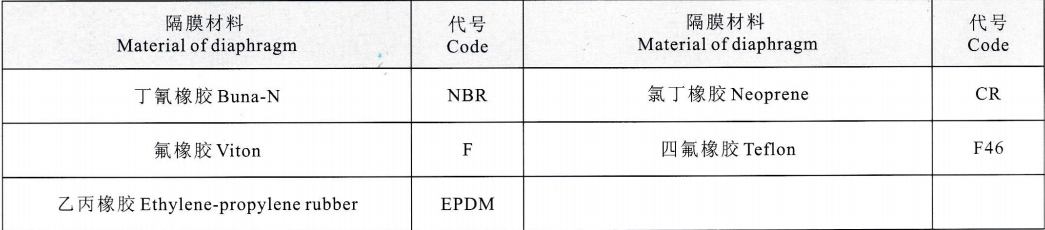

隔膜材料代号 Code of materials for diaphragm

本公司QBK系列气动隔膜泵有两大系列,其中QBK1出口在中间,QBK2出口在侧边。订货时,要告之使用环境

温度、介质、流量、扬程、压力、泵体材料、隔膜材料

environment, temperature, medium flow rate, head, pressure, materials of pump body and diaphragm when order. SIde connection. Please specify

We have two main series of QBK product, one is QbKI which with center connection, the other is QBK2 with

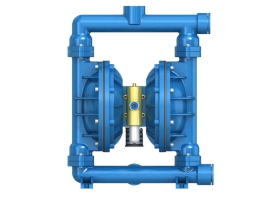

产品概述 Performance summary

QBK气动隔膜泵是我公司开发的第三代气动隔膜泵,具有使用寿命长,不会停顿等优点,它既能抽送流动的液体,又能输送一些不易流动的介质,具有自吸泵、潜水泵、屏蔽泵、泥浆泵和杂质泵等输送机械

的许多优点。

1、不需灌引水,吸程高达5m,扬程达70m,出口压力≥6bar

2、流动宽敞,通过性能好,允许通过最大颗粒直径达10mm。抽送泥浆、杂质时,对泵磨损甚微;

3、扬程、流量可通过气阀开度实现无级调节(气压调节在1-7bar之间)

4、该泵无旋转部件,没有轴封,隔膜等抽送的介质与泵的运动部件、工件介质完全隔开,所输送的介质不会向外泄漏。所以抽送有毒、易发挥或腐蚀性介质时,不会造成环境污染和危害人身安全

5、不必用电。在易燃、易爆场所使用安全可靠。

6、可以浸没在介质中工作

7,使用方便、工作可靠、开停只需简单地打开和关闭气体阀门,即使由于意外情况而长时间无介质运行或突然停机,泵也不会因此而损坏

旦超负荷,泵会自动地停机,具有自我保护性能,当负荷恢复正常后,又能自动启动运行。

8、结构简单、易损件少,该泵结构简单,安装、维修方便,泵输送的介质不会接触到配气阀,联杆等运动部件,不象其他类型的泵因转子、活塞、齿轮、叶片等部件的磨损而使性能逐步下降

9、可输送较粘的液体(粘度在1万厘泊以下)

10、本泵无须用油润滑,即使空转,对泵也无任何影响,这是该泵最大特点。

QBK is coosai's new developed series of AODd pump which is also the third generation, it has the virtue of long service life

and nonstop operation, not only it can convey some uneasy flowed medium, with the merits the merits of self-pumping pump,

diving pump, shield pump, slurry pump and impurity pump etc

1.Ir's unnecessary to pour the drawing water, the suction lift reaches 5m height, the delivery lift reaches 70m length

2. Wide flow and good performance. The diameter allowed to pass the max grain reaches 10mm. The damage is very less to

the pump while exhausting the slurry and impurit

3. The delivery lift and flow can pass the pneumatic valve open to realize the step less adjustment( the pneumatic pressure

adjust ment is between 1-7bar)

4.This pump has no rotary parts and no bearing seals. The diaphragm will completely separate the exhausted medium and

pump running parts, working medium. The conveyed medium can't be leaked outside. Thus it will not cause the environmental

pollution and human body safety dangerous while exhausting the toxin and flammable or corrosive medium

5. No electricity. It's safe and reliable while using in the flammable and explore places

6. It can be soaked in medium

7.It's convenient to use and reliable to work. Only open or close the gas valve body while starting or stopping. Even if no

medium operation or pausing suddenly for long time because of accident matters, the pump will not be damaged caused by this

Once over loading, the pump will automatically stop and possesses the self protection function. When the load recovers normally

it also can start automatically

8.Simple structure and less wearing parts. This pump is simple in structure, installation and maintenance. The medium

conveyed by the pump will not touch the matched pneumatic valve and coupling lever etc. Not like other kinds pumps, the

performance will drop down gradually because of the damages of rotor, gear and vane etc

9. It can transmit the adhesive liquid( the viscosity is below 10000 centipoises)

10.This pump needn t the oil lubricant. Even if idling, it has any influence to the pump. This is a characteristic of this pump

系统连接示意图 System connection schematic diagram

备注:在使用QBK气动隔膜泵时,要安装空气过滤器,以滤去压缩空气中的水分,并在泵的出口安装压力表,避免因压力过高损害泵,在泵不工作时应及时清洗泵,避免因凝固损坏泵。

Note: When the air operated diaphragm pumpworks. install the air filter to leach the moisturefrom the compressed air, and install themanometer at the outlet of pump, so to avoid

damaging as too high pressure, when the pumpdoesn't need work, please clean it in time toprevent from concreting

更多隔膜泵知识关注上海浙瓯泵阀制造有限公司

© 2023 上海浙瓯泵阀制造有限公司 版权所有

© 2023 上海浙瓯泵阀制造有限公司 版权所有