GHK型不锈钢化工泵的概述:

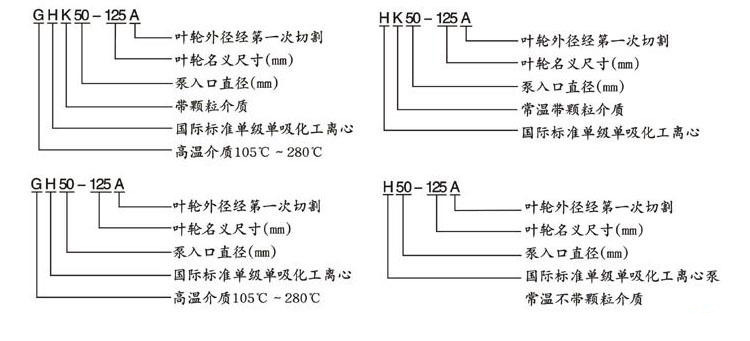

GHK型化工泵是单级单吸(轴向吸入)悬臂式离心泵,是IH型派生产品,供输送高温带颗粒的、具有腐蚀性液体、是解决IH型不能理想使用的新产品。磁力驱动泵其额定性能和尺寸等效采用国际标准ISO2858,技术条件采用GB/T5656-1994标准,具有使用性能范围广、效率高和维修方便的特点,是技术改进型节能新产品。

GHK型不锈钢化工泵的适用范围:

GHK型化工泵可输送带颗粒及280℃以下的具有腐蚀性的液体,也可用于输送常温带颗粒及类似于水质液体

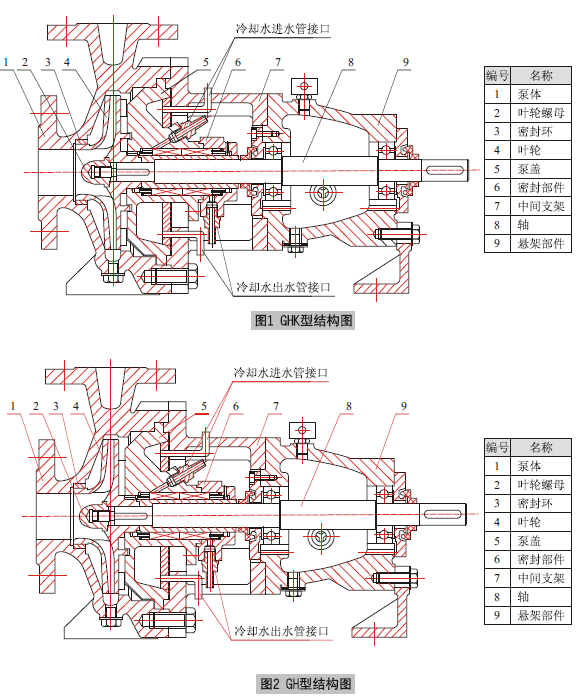

GHK型不锈钢化工泵的结构:

GHK型化工泵是全国泵行业采用ISO国际标准联合设计的系列产品,其主要由泵体、密封环、叶轮螺母、泵盖、密封部件、中间支架、轴、悬架部件等组成。

GHK型不锈钢化工泵的的产品性能范围:

流量Q:6.3~400m3/h

扬程H:5~125m

配套功率:0.55~110kw

进口直径:50~200mm

工作压力:1.6Mpa

GHK型不锈钢化工泵性能参数:

| 型号 | 流量 | 扬程 | 转速 | 轴功率|配用功率 | 效率 | 必需气蚀余量 | |

| GHK50-125 | 12.5 | 20 | 2900 | 1.33 | 2.2 | 51 | 2 |

| 6.3 | 5 | 1450 | 0.19 | 0.55 | 45 | 2 | |

| GHK50-160 | 12.5 | 32 | 2900 | 2.37 | 3 | 46 | 2 |

| 12.5 | 12.5 | 1450 | 0.93 | 1.5 | 46 | 2 | |

| GHK50-200 | 12.5 | 50 | 2900 | 4.36 | 5.5 | 39 | 2 |

| 6.3 | 12.5 | 1450 | 0.65 | 1.1 | 33 | 2 | |

| GHK50-250 | 12.5 | 80 | 2900 | 8.25 | 11 | 33 | 2 |

| 6.3 | 20 | 1450 | 1.27 | 2.2 | 27 | 2 | |

| GHK65-125 | 25 | 20 | 2900 | 2.2 | 3 | 62 | 2 |

| 12.5 | 5 | 1450 | 0.31 | 0.55 | 55 | 2 | |

| GHK65-160 | 25 | 32 | 2900 | 3.82 | 5.5 | 57 | 2 |

| 12.5 | 8 | 1450 | 0.53 | 0.75 | 51 | 2 | |

| GHK65-200 | 25 | 50 | 2900 | 6.55 | 11 | 52 | 2 |

| 12.5 | 12.5 | 1450 | 0.93 | 1.5 | 46 | 2 | |

| GHK65-250 | 25 | 80 | 2900 | 11.84 | 15 | 46 | 2 |

| 12.5 | 20 | 1450 | 1.75 | 3 | 39 | 2 | |

| GHK65-315 | 25 | 125 | 2900 | 21.8 | 30 | 39 | 2 |

| 12.5 | 32 | 1450 | 3.3 | 5.5 | 33 | 2 | |

| GHK80-125 | 50 | 20 | 2900 | 3.95 | 5.5 | 69 | 3 |

| 25 | 5 | 1450 | 0.53 | 0.75 | 64 | 2.5 | |

| GHK80-160 | 50 | 32 | 2900 | 6.51 | 11 | 67 | 2.3 |

| 25 | 8 | 1450 | 0.88 | 1.5 | 62 | 2.3 | |

| GHK80-200 | 50 | 50 | 2900 | 10.8 | 15 | 63 | 2.5 |

| 25 | 12.5 | 1450 | 1.49 | 2.2 | 57 | 2 | |

| GHK80-250 | 50 | 80 | 2900 | 20.57 | 30 | 53 | 2.5 |

| 25 | 20 | 1450 | 2.72 | 5.5 | 50 | 2 | |

| GHK80-315 | 50 | 125 | 2900 | 34.1 | 45 | 50 | 2.5 |

| 25 | 32 | 1450 | 4.54 | 7.5 | 48 | 2.5 | |

| GHK100-125 | 100 | 20 | 2900 | 7.47 | 11 | 73 | 4.2 |

| 50 | 5 | 1450 | 0.99 | 1.5 | 69 | 3.4 | |

| GHK100-160 | 100 | 32 | 2900 | 11.9 | 15 | 73 | 4.3 |

| 50 | 8 | 1450 | 1.58 | 2.2 | 69 | 3.4 | |

| GHK100-200 | 100 | 50 | 2900 | 18.9 | 22 | 72 | 3.9 |

| 50 | 12.5 | 1450 | 2.5 | 3 | 68 | 2.5 | |

| GHK100-250 | 100 | 80 | 2900 | 32.06 | 37 | 68 | 3.6 |

| 50 | 20 | 1450 | 4.33 | 5.5 | 63 | 2.5 | |

| GHK100-315 | 100 | 125 | 2900 | 54.94 | 75 | 62 | 3.2 |

| 50 | 32 | 1450 | 7.52 | 11 | 58 | 2 | |

| GHK125-200 | 200 | 50 | 2900 | 35.39 | 45 | 77 | 5 |

| 100 | 12.5 | 1450 | 4.66 | 7.5 | 73 | 2.9 | |

| GHK125-250 | 200 | 80 | 2900 | 58.13 | 75 | 75 | 4.5 |

| 100 | 20 | 1450 | 7.56 | 11 | 72 | 2.3 | |

| GHK125-315 | 200 | 125 | 2900 | 94.62 | 110 | 72 | 4.5 |

| 100 | 32 | 1450 | 13.42 | 22 | 65 | 2.5 | |

| GHK125-400 | 100 | 50 | 1450 | 24.77 | 30 | 55 | 2.5 |

| GHK150-250 | 200 | 20 | 1450 | 14.1 | 18.5 | 77 | 2.8 |

| GHK150-315 | 200 | 32 | 1450 | 23.25 | 30 | 75 | 2.8 |

| GHK150-400 | 200 | 50 | 1450 | 38.93 | 55 | 70 | 2.5 |

| GHK200-250 | 400 | 20 | 1450 | 27.59 | 37 | 79 | 2.8 |

| GHK200-315 | 400 | 32 | 1450 | 44.15 | 55 | 79 | 3.5 |

| GHK200-400 | 400 | 50 | 1450 | 69.87 | 90 | 78 | 3.5 |

点击图片放大

点击图片放大 © 2023 上海浙瓯泵阀制造有限公司 版权所有

© 2023 上海浙瓯泵阀制造有限公司 版权所有